A quick post for a quick project. If I had a gardening blog, this project would belong there but there is wood involved so I'll mention it here. Every garden needs a bit of whimsy. I've been reading about the plight of bees lately and learned about mason bees. They live solitary lives rather than in colonies and like to lay their eggs in small tunnels. The centre portion is made of pine with 5" holes drilled in it. I found the hollow sticks in a nearby park. I think they are a bit too big but they were all I could find this spring. I may try to replace them next year if no one moves in. The glass beads are a bit of an experiment. They're placed in a cookie sheet so that the whole thing collects water. The theory is that the bees will be able to drink from it. If I don't get any tenants it may be the bright colours and shiny surfaces causing the problems. I'll leave them for now and replace with small pebbles next year. I've got it on the ground for the picture but I've since attached it to a Southeast facing fence.

If you're interested in learning more about mason bees I found a lot of great information on this site.

(http://www.foxleas.com/bee_house.htm)

Sunday, May 25, 2014

Doors Are My Nemesis

Doors are my nemesis.

I have no idea why but doors are always the part of a project that slow me down. I go gangbusters on the main part of the project and then when it comes time to do the doors, I make every excuse to not get started on them.

This particular project actually started early last year. I typically start gardening in March so it's usually best if I get a project done before the end of February, otherwise it can get stuck. That was definitely the case with this one. Majority of the piece was done quickly but I just had the doors remaining. I'm not even sure why I procrastinate on them. They're not overly difficult and if you mess them up you can always start over without losing too much time or material. If I had to guess it's probably from some of my shop projects. The doors always came last since the rest of the project was already functional without them. That isn't the case for a finished piece like this set of book shelves.

Well enough ranting about doors. I've had a nice set of book shelves on my bucket list for a while. I had done a built in at our previous house which of course couldn't come with us when we moved so this time I wanted a nice stand alone piece. I went with this plan from PlansNow.com because I liked the fact that it looked like a piece of furniture. Having the shelves covered will keep out the dust and I got to try my hand at installing a lock. If you haven't done one before, make sure you understand what 'distance to pin' means when buying the lock. I had to go back a second time.

Installing the hinges has become a fairly routine task for me now. For this piece, despite having to align three sets of hinges per side, careful layout and clean chisel work turned out perfectly. The wood is white oak with an aniline dye and wipe on polyurethane for the finish. The plugs are purple heart. All the important parts are solid wood though I did go with plywood for the side panels and the shelves. The side panels turned out fine but I think next time I'll try to go with solid wood for the shelves. Despite being a total of 1" thick, there is still a small amount of bow in the shelves.

I have no idea why but doors are always the part of a project that slow me down. I go gangbusters on the main part of the project and then when it comes time to do the doors, I make every excuse to not get started on them.

This particular project actually started early last year. I typically start gardening in March so it's usually best if I get a project done before the end of February, otherwise it can get stuck. That was definitely the case with this one. Majority of the piece was done quickly but I just had the doors remaining. I'm not even sure why I procrastinate on them. They're not overly difficult and if you mess them up you can always start over without losing too much time or material. If I had to guess it's probably from some of my shop projects. The doors always came last since the rest of the project was already functional without them. That isn't the case for a finished piece like this set of book shelves.

Well enough ranting about doors. I've had a nice set of book shelves on my bucket list for a while. I had done a built in at our previous house which of course couldn't come with us when we moved so this time I wanted a nice stand alone piece. I went with this plan from PlansNow.com because I liked the fact that it looked like a piece of furniture. Having the shelves covered will keep out the dust and I got to try my hand at installing a lock. If you haven't done one before, make sure you understand what 'distance to pin' means when buying the lock. I had to go back a second time.

Installing the hinges has become a fairly routine task for me now. For this piece, despite having to align three sets of hinges per side, careful layout and clean chisel work turned out perfectly. The wood is white oak with an aniline dye and wipe on polyurethane for the finish. The plugs are purple heart. All the important parts are solid wood though I did go with plywood for the side panels and the shelves. The side panels turned out fine but I think next time I'll try to go with solid wood for the shelves. Despite being a total of 1" thick, there is still a small amount of bow in the shelves.

Saturday, January 4, 2014

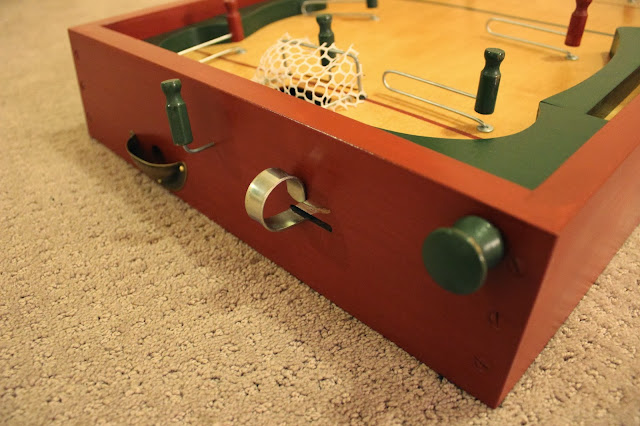

Lee Valley Monroe Style Table Hockey Game

Whenever I went to my aunts and uncles houses as a kid the thing I always enjoyed was playing with the old games they had. I'm thirty six and my Dad was the youngest in his family so some of his brothers and sisters had kids that were 20 years older. This meant a lot of vintage games. This Christmas I decided to start a new tradition for my kids. I would build a vintage game for them each Christmas. The plan is to keep them hidden for most of the year and bring them out around Christmas time so they can rediscover them each year.

The first project was somewhat complicated but comes as a kit from Lee Valley. It's based on a table hockey game by Monroe and this particular version dates to about the 1950's. The instructions were fairly complete but could definitely have benefitted from a few more pictures which is why I've included multiple views of the finished project in this posting. I searched online and there weren't very many images to be found so hopefully this post helps someone in the future. (Feel free to point out anything I might have gotten incorrect.)

I kept to the plan for the most part however I made the sides a bit beefier. I want this to last a long time. The finish is milk paint and shellac.

I kept to the plan for the most part however I made the sides a bit beefier. I want this to last a long time. The finish is milk paint and shellac.

The kids really enjoyed playing with it this year and when they seemed done I tucked it away under a bed for us to find again next year.

A Reborn Kitchen Table

This kitchen table originally belonged to my in-laws. They used it for several years and then my wife started using it in her classroom. The top and apron were all particle board so needless to say, several years of students sitting on it left it in bad shape. Most people would have thrown it out after the first leg fell off however, despite it's failings the legs were solid wood and deserved a second chance. I decided I would give it a new life by replacing the top and aprons and improving on the construction.

For now it's being used to house my daughter's Lego Friends Heart Lake City but it could easily convert back to a kitchen table when she's done.

A Few Quick Projects

Although I enjoy the complexity of putting together larger pieces of furniture sometimes it's nice to do smaller projects just so you can leave the shop saying you've finished something. These projects all fit the bill. The first is a wooden mallet. I've always wanted one but didn't want to pay for it. I wanted to make it. (Let's ignore that it took about $1500 of turning equipment to get the point where I could make it.) It's a simple design from a recent article of Fine Woodworking. Wood is white oak and the finish is boiled linseed oil. This was my first turning project and was done in a single session.

Although I enjoy the complexity of putting together larger pieces of furniture sometimes it's nice to do smaller projects just so you can leave the shop saying you've finished something. These projects all fit the bill. The first is a wooden mallet. I've always wanted one but didn't want to pay for it. I wanted to make it. (Let's ignore that it took about $1500 of turning equipment to get the point where I could make it.) It's a simple design from a recent article of Fine Woodworking. Wood is white oak and the finish is boiled linseed oil. This was my first turning project and was done in a single session.The final project was a clipboard for my wife who is a teacher. I purchased the hardware at Lee Valley and the quilted maple came from my cousin. I believe he got it from a neighbours firewood pile. The wood down the centre is walnut. Boiled linseed oil and shellac for this one. I was amazed that I could get two coats of oil and four coats of shellac on in a single day. If I had to list one lesson for new woodworkers it's to avoid the fancy one function tools, finishes etc. and try the traditional aspects of woodworking first as there are definitely good reasons they were used for so many years.

Saturday, November 23, 2013

A Woodworkers Wood Turning Hanging Tool Chest

I am a woodworker and not a woodturner. I also get the sense that most woodturners are not woodworkers. (There are of course notable exceptions especially when it comes to Shaker furniture.) The reason I've come to this conclusion was because of how difficult it was to find any pictures of cabinets for woodturning tools. Most turners seem to throw their tools in some PVC pipe and call it a day. I only intend to do simple projects and pieces for furniture when I'm turning and I didn't want my turning tools ending up all over the shop. This includes the tools and the lathe accessories.

After some research I worked out the features I felt I needed.

1) Enough room for my starter turning set.

2) A couple shelves for checks etc.

3) Some drawers for bits and pieces.

4) A door. (To keep the woodworking dust out.)

The dimensions came during the design process. The tools had to be spread out enough to get your fingers around them and I wanted at least one spare spot. This meant a width of 20". I figured a 1.5 to 1 ratio was good which left the height at 30". After that it was just a matter of picking inside dimensions that fit the tools.

I purchased a Forrester finger jointing blade and used the 3/8" size for the joinery. The drawers were are pinned lap joints with a hole for a pull. I sized the drawers based on a few accessories I needed to store. The door panel is a terrible piece of shop grade plywood that I cleaned up by filling the holes and using a half can of old spray paint. The door handle is a traditional ring pull. I've done a few turning projects since this was created and it's very nice being able to put all my tools away when I'm done and not have to worry about them. I now realize I need to do the same for my woodworking tools.

A Pair of Hope Chests

This past September by brother got married and I decided I would make them a hope chest. I wanted something that wasn't too big and there was a plan I'd seen in Fine Woodworking that I thought would work well. The original plan called for cherry which is a joy to work and was the look I was working for. It was also an opportunity to try out shellac for the first time. The picture in the plan looked great with brass hardware however the combination of the design, finish and hardware gives it the appearance of a coffin when closed. (Three people mentioned it to me.)

Although I'd done a hope chest in the past and none of the techniques were new to me I wanted to be very precise in my joinery so I decided I would make two. The first would be in poplar which is much cheaper and with a painted finish it didn't matter if I made minor mistakes. (Or major ones like when I cut a tail in the wrong direction.) I did both pieces at the same time, one machine set up at a time. It probably only added about 25% in time to make the second and now I have a spare to hand out as a gift to someone else. I'll have a separate post on how I finished it.

I tried a few new techniques on this project. The first was using a table saw to do the cuts that would ordinarily be done by a handsaw. After that it was all hand tools. I don't use a hand saw often enough to keep it perfectly straight so it saves time and improves accuracy and this joint is much more prominent then a drawer that remains hidden away. The other technique that I was planning on but never got to was to use a shooting board for the mitres. I didn't get a jack plane in time but I've tried it since and it makes it much easier to sneak up on the final fit.

The final new technique for me was using shellac. I was planning on using boiled linseed as a base coat but I've previously learned my lesson about using oil on the inside of a chest. (11 years later and it still has a distinct smell.) Shellac will apparently cover the smell but I didn't want to chance it and I liked the look of just orange shellac. Application by brush was not too bad but I consistently got lap marks on the corners after each coat that had to be rubbed away with steel wool. Next time I'll spray it.

Although I'd done a hope chest in the past and none of the techniques were new to me I wanted to be very precise in my joinery so I decided I would make two. The first would be in poplar which is much cheaper and with a painted finish it didn't matter if I made minor mistakes. (Or major ones like when I cut a tail in the wrong direction.) I did both pieces at the same time, one machine set up at a time. It probably only added about 25% in time to make the second and now I have a spare to hand out as a gift to someone else. I'll have a separate post on how I finished it.

I tried a few new techniques on this project. The first was using a table saw to do the cuts that would ordinarily be done by a handsaw. After that it was all hand tools. I don't use a hand saw often enough to keep it perfectly straight so it saves time and improves accuracy and this joint is much more prominent then a drawer that remains hidden away. The other technique that I was planning on but never got to was to use a shooting board for the mitres. I didn't get a jack plane in time but I've tried it since and it makes it much easier to sneak up on the final fit.

The final new technique for me was using shellac. I was planning on using boiled linseed as a base coat but I've previously learned my lesson about using oil on the inside of a chest. (11 years later and it still has a distinct smell.) Shellac will apparently cover the smell but I didn't want to chance it and I liked the look of just orange shellac. Application by brush was not too bad but I consistently got lap marks on the corners after each coat that had to be rubbed away with steel wool. Next time I'll spray it.

Subscribe to:

Posts (Atom)