Our old kitchen table wasn't too exciting. It was round with drop leaves and a pedestal base and was a mass produced item. It served us well but needed to be refinished after too many hot dishes had been placed on it and several poorly supervised art projects had taken place without any thing to protect it. It was solid wood so refinishing was an option however this was a good opportunity to build something new.

Although we have a dining room, most of the eating takes place in the kitchen even when we have a couple of guests over. The 30 inch round table was a tight squeeze so this time we were looking for something a bit bigger. I've always liked the trestle table for it's ease of construction and it's timeless style. I didn't want something too contemporary that would look out of place in a decade. I also wanted to use good materials and proper construction so it would last a lifetime.

I can't really take any credit for the design of course since it's been around for a few hundred years. I took the base from a Fine Woodworking article and the finish technique from a table by Doucette and Wolfe. The top is solid cherry with bread board ends and the base is solid maple with pinned mortise and tenons. I had the most fun with the distressed finish on the base. A coat of red dye, followed by red milk paint, then black milk paint. The black milk paint was then sanded through enough to see the red before getting a few coats of a wipe on poly. I probably could have distressed the black a bit more but that will happen with time. So far I'm amazed at how stable this design is. There is enough play in the base that all legs sit on the floor without any wobble. So far the top has stayed nice and flat although I do have some concerns with how far apart I made the legs. At 62 inches for the top and a full four feet between centres on the legs it's a pretty long span and I'm concerned it may sag in the middle. If it does I'll just add a support immediately underneath. Even if it looks like an add on it will just be part of the tables history. Maybe it won't even be me that needs to do it.

Saturday, December 27, 2014

A Pair of Gun Cabinets

In 1973 the Royal Canadian Mounted Police released a 100 anniversary gun to it's members. They were available to purchase and the first set sold out so quickly there was a second run. My father-in-law was a member at the time and purchase two of them from the first run. He moved a lot in the early years and the guns always came with him. He eventually had twin boys and decided he would give the guns to them. The only thing left to do was to get them mounted in a secure cabinet and that's where I came in.

The rules on gun storage aren't very strict other than that they have to be secured by a lock. The design is mostly my own and consists of a five inch deep dovetailed box with a spline reinforced door panel. Butt hinges and an older style lock with the two toothed key finish up the wood working. The interior panel is a red felt on 1/8 inch backer board and the mounts are simply two blocks of wood custom fit to each gun covered in felt. They keep the gun in position without being too invasive. It was a fun project.

The rules on gun storage aren't very strict other than that they have to be secured by a lock. The design is mostly my own and consists of a five inch deep dovetailed box with a spline reinforced door panel. Butt hinges and an older style lock with the two toothed key finish up the wood working. The interior panel is a red felt on 1/8 inch backer board and the mounts are simply two blocks of wood custom fit to each gun covered in felt. They keep the gun in position without being too invasive. It was a fun project.

Tool Cabinet (Almost Done)

Drawers, drawers, drawers. Why is it always the drawers that hold up completion? My hand tools were starting to add up and I had several layers of them in a drawer in lower cabinets. With the purchase of another Lee valley plane it seemed like it was time to build a better place to store them. I'm not entirely sure what I need in a wall cabinet so in some ways this is a prototype though I will likely use it for several years. I kept materials simple using poplar and baltic birch plywood. The joinery was through dovetails on the case and finger joints for the doors. The first major mistake came with the finger joints and will be the reason that I keep the doors open most of the time. I flipped one of the doors when cutting the grooves for the plywood panels and as a result the finger joints run top to bottom on one door and left to right on another. Not a huge mistake especially when the doors are open but noticeable when the doors are closed. Rather than trying to create too many fitted locations for little bits and pieces I opted for drawers. My rough sketch plans showed four columns of three but a second mistake resulted in the drawer section being split into three instead of four. We'll call this one a design modification. The only real impact was that I find that drawers that are longer than they are wide slide better in their opening. These are almost square so it shouldn't be too bad. Everything you see here has been finished, and the only thing outstanding is the drawers. I'm hoping to get to those in the next couple weeks. I'm finding even the little shelves are handy though. The only issue is that things get pushed to the back and are hard to retrieve. Drawers should help that.

Sunday, May 25, 2014

Building a 'B' House

A quick post for a quick project. If I had a gardening blog, this project would belong there but there is wood involved so I'll mention it here. Every garden needs a bit of whimsy. I've been reading about the plight of bees lately and learned about mason bees. They live solitary lives rather than in colonies and like to lay their eggs in small tunnels. The centre portion is made of pine with 5" holes drilled in it. I found the hollow sticks in a nearby park. I think they are a bit too big but they were all I could find this spring. I may try to replace them next year if no one moves in. The glass beads are a bit of an experiment. They're placed in a cookie sheet so that the whole thing collects water. The theory is that the bees will be able to drink from it. If I don't get any tenants it may be the bright colours and shiny surfaces causing the problems. I'll leave them for now and replace with small pebbles next year. I've got it on the ground for the picture but I've since attached it to a Southeast facing fence.

If you're interested in learning more about mason bees I found a lot of great information on this site.

(http://www.foxleas.com/bee_house.htm)

If you're interested in learning more about mason bees I found a lot of great information on this site.

(http://www.foxleas.com/bee_house.htm)

Doors Are My Nemesis

Doors are my nemesis.

I have no idea why but doors are always the part of a project that slow me down. I go gangbusters on the main part of the project and then when it comes time to do the doors, I make every excuse to not get started on them.

This particular project actually started early last year. I typically start gardening in March so it's usually best if I get a project done before the end of February, otherwise it can get stuck. That was definitely the case with this one. Majority of the piece was done quickly but I just had the doors remaining. I'm not even sure why I procrastinate on them. They're not overly difficult and if you mess them up you can always start over without losing too much time or material. If I had to guess it's probably from some of my shop projects. The doors always came last since the rest of the project was already functional without them. That isn't the case for a finished piece like this set of book shelves.

Well enough ranting about doors. I've had a nice set of book shelves on my bucket list for a while. I had done a built in at our previous house which of course couldn't come with us when we moved so this time I wanted a nice stand alone piece. I went with this plan from PlansNow.com because I liked the fact that it looked like a piece of furniture. Having the shelves covered will keep out the dust and I got to try my hand at installing a lock. If you haven't done one before, make sure you understand what 'distance to pin' means when buying the lock. I had to go back a second time.

Installing the hinges has become a fairly routine task for me now. For this piece, despite having to align three sets of hinges per side, careful layout and clean chisel work turned out perfectly. The wood is white oak with an aniline dye and wipe on polyurethane for the finish. The plugs are purple heart. All the important parts are solid wood though I did go with plywood for the side panels and the shelves. The side panels turned out fine but I think next time I'll try to go with solid wood for the shelves. Despite being a total of 1" thick, there is still a small amount of bow in the shelves.

I have no idea why but doors are always the part of a project that slow me down. I go gangbusters on the main part of the project and then when it comes time to do the doors, I make every excuse to not get started on them.

This particular project actually started early last year. I typically start gardening in March so it's usually best if I get a project done before the end of February, otherwise it can get stuck. That was definitely the case with this one. Majority of the piece was done quickly but I just had the doors remaining. I'm not even sure why I procrastinate on them. They're not overly difficult and if you mess them up you can always start over without losing too much time or material. If I had to guess it's probably from some of my shop projects. The doors always came last since the rest of the project was already functional without them. That isn't the case for a finished piece like this set of book shelves.

Well enough ranting about doors. I've had a nice set of book shelves on my bucket list for a while. I had done a built in at our previous house which of course couldn't come with us when we moved so this time I wanted a nice stand alone piece. I went with this plan from PlansNow.com because I liked the fact that it looked like a piece of furniture. Having the shelves covered will keep out the dust and I got to try my hand at installing a lock. If you haven't done one before, make sure you understand what 'distance to pin' means when buying the lock. I had to go back a second time.

Installing the hinges has become a fairly routine task for me now. For this piece, despite having to align three sets of hinges per side, careful layout and clean chisel work turned out perfectly. The wood is white oak with an aniline dye and wipe on polyurethane for the finish. The plugs are purple heart. All the important parts are solid wood though I did go with plywood for the side panels and the shelves. The side panels turned out fine but I think next time I'll try to go with solid wood for the shelves. Despite being a total of 1" thick, there is still a small amount of bow in the shelves.

Saturday, January 4, 2014

Lee Valley Monroe Style Table Hockey Game

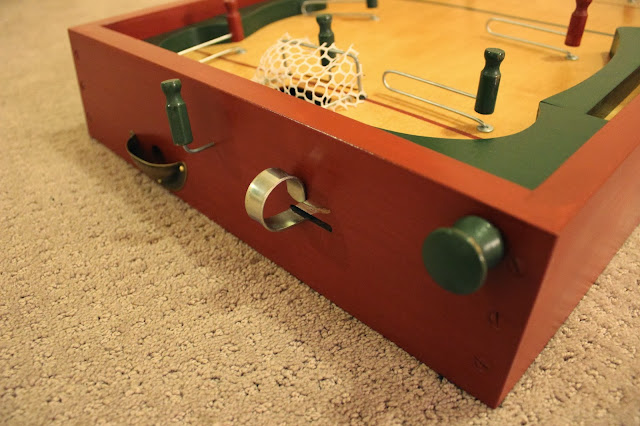

Whenever I went to my aunts and uncles houses as a kid the thing I always enjoyed was playing with the old games they had. I'm thirty six and my Dad was the youngest in his family so some of his brothers and sisters had kids that were 20 years older. This meant a lot of vintage games. This Christmas I decided to start a new tradition for my kids. I would build a vintage game for them each Christmas. The plan is to keep them hidden for most of the year and bring them out around Christmas time so they can rediscover them each year.

The first project was somewhat complicated but comes as a kit from Lee Valley. It's based on a table hockey game by Monroe and this particular version dates to about the 1950's. The instructions were fairly complete but could definitely have benefitted from a few more pictures which is why I've included multiple views of the finished project in this posting. I searched online and there weren't very many images to be found so hopefully this post helps someone in the future. (Feel free to point out anything I might have gotten incorrect.)

I kept to the plan for the most part however I made the sides a bit beefier. I want this to last a long time. The finish is milk paint and shellac.

I kept to the plan for the most part however I made the sides a bit beefier. I want this to last a long time. The finish is milk paint and shellac.

The kids really enjoyed playing with it this year and when they seemed done I tucked it away under a bed for us to find again next year.

A Reborn Kitchen Table

This kitchen table originally belonged to my in-laws. They used it for several years and then my wife started using it in her classroom. The top and apron were all particle board so needless to say, several years of students sitting on it left it in bad shape. Most people would have thrown it out after the first leg fell off however, despite it's failings the legs were solid wood and deserved a second chance. I decided I would give it a new life by replacing the top and aprons and improving on the construction.

For now it's being used to house my daughter's Lego Friends Heart Lake City but it could easily convert back to a kitchen table when she's done.

A Few Quick Projects

Although I enjoy the complexity of putting together larger pieces of furniture sometimes it's nice to do smaller projects just so you can leave the shop saying you've finished something. These projects all fit the bill. The first is a wooden mallet. I've always wanted one but didn't want to pay for it. I wanted to make it. (Let's ignore that it took about $1500 of turning equipment to get the point where I could make it.) It's a simple design from a recent article of Fine Woodworking. Wood is white oak and the finish is boiled linseed oil. This was my first turning project and was done in a single session.

Although I enjoy the complexity of putting together larger pieces of furniture sometimes it's nice to do smaller projects just so you can leave the shop saying you've finished something. These projects all fit the bill. The first is a wooden mallet. I've always wanted one but didn't want to pay for it. I wanted to make it. (Let's ignore that it took about $1500 of turning equipment to get the point where I could make it.) It's a simple design from a recent article of Fine Woodworking. Wood is white oak and the finish is boiled linseed oil. This was my first turning project and was done in a single session.The final project was a clipboard for my wife who is a teacher. I purchased the hardware at Lee Valley and the quilted maple came from my cousin. I believe he got it from a neighbours firewood pile. The wood down the centre is walnut. Boiled linseed oil and shellac for this one. I was amazed that I could get two coats of oil and four coats of shellac on in a single day. If I had to list one lesson for new woodworkers it's to avoid the fancy one function tools, finishes etc. and try the traditional aspects of woodworking first as there are definitely good reasons they were used for so many years.

Subscribe to:

Comments (Atom)